Shearfab Ltd are sheetmetal fabrication experts who aim to keep on top of the game with the latest technologies.

Sheetmetal fabrication as a process has come a long way thanks to continuous advances in technology. In recent years, the manufacturing sector has seen a surge in innovations that are changing the way metal components are manufactured and worked on. Cutting-edge technologies like laser cutting, CNC machining, and 3D printing are reshaping the industry.

The widespread adoption of laser cutting technology is one of the most significant advances in sheetmetal fabrication. Laser cutting is one of the most precise cutting methods, allowing manufacturers to cut accurate complex shapes. It can be used on different materials, allowing for a wider range of finished products, and can cut quickly through thick materials leading to a more efficient process. Its precision also makes it an extremely consistent and reliable process, ensuring that each cut is identical to the next.

CNC machining has been a part of sheetmetal fabrication for many years, but recent advances have made it a staple part of the manufacturing process. CNC machines are an excellent solution for automation, streamlining production, reducing human error, and enhancing overall productivity.

3d printing is perhaps one of the most groundbreaking innovations in recent years, allowing manufacturers to build components layer by layer based on a digital design. 3d printing allows for the creation of complex and more intricate parts that were harder or impossible to achieve with traditional methods.

These technologies are not only enhancing precision and efficiency but also unlocking new possibilities in design and the overall capabilities of sheetmetal fabrication.

At Shearfab we have 30 years’ experience in sheet metalwork fabrication. Our extensive CAD department, CNC punching and laser-cutting equipment, welding, fabrication, and full in-house painting facility, coupled with our delivery fleet ensures customers receive a complete, quality-controlled turnkey project all from one site.

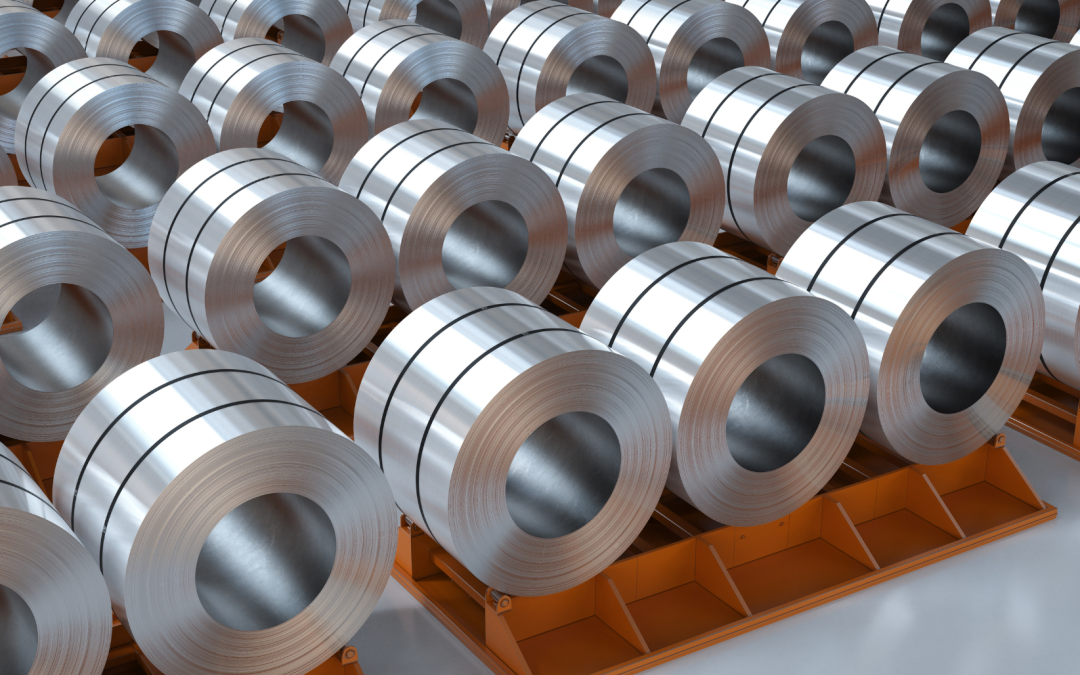

Shearfab’s one-stop-shop sheetmetal fabrication facilities allows Shearfab to produce a surprisingly diverse range of mild steel and aluminium products. We work closely with our customers to complete quality-controlled turnkey projects from conception to installation. We produce structural steel to BS EN IEC 1090 Execution Class 2.

To learn more about our capabilities in sheetmetal fabrication contact a member of our team today.